We receive a number of phone calls every week asking how to specify impact barriers, in particular the following issues:

- How many Post and Lap bolts do I need?

- How many lengths of barrier do I need?

- How many posts do I need?

- Which type of post do I need?

This post is intended to explain exactly how to specify the sizes of impact barriers and when to use custom length pieces.

Impact Barrier Basics

The most important concept to understand about standard impact barrier is how barrier sections and ends are connected together.

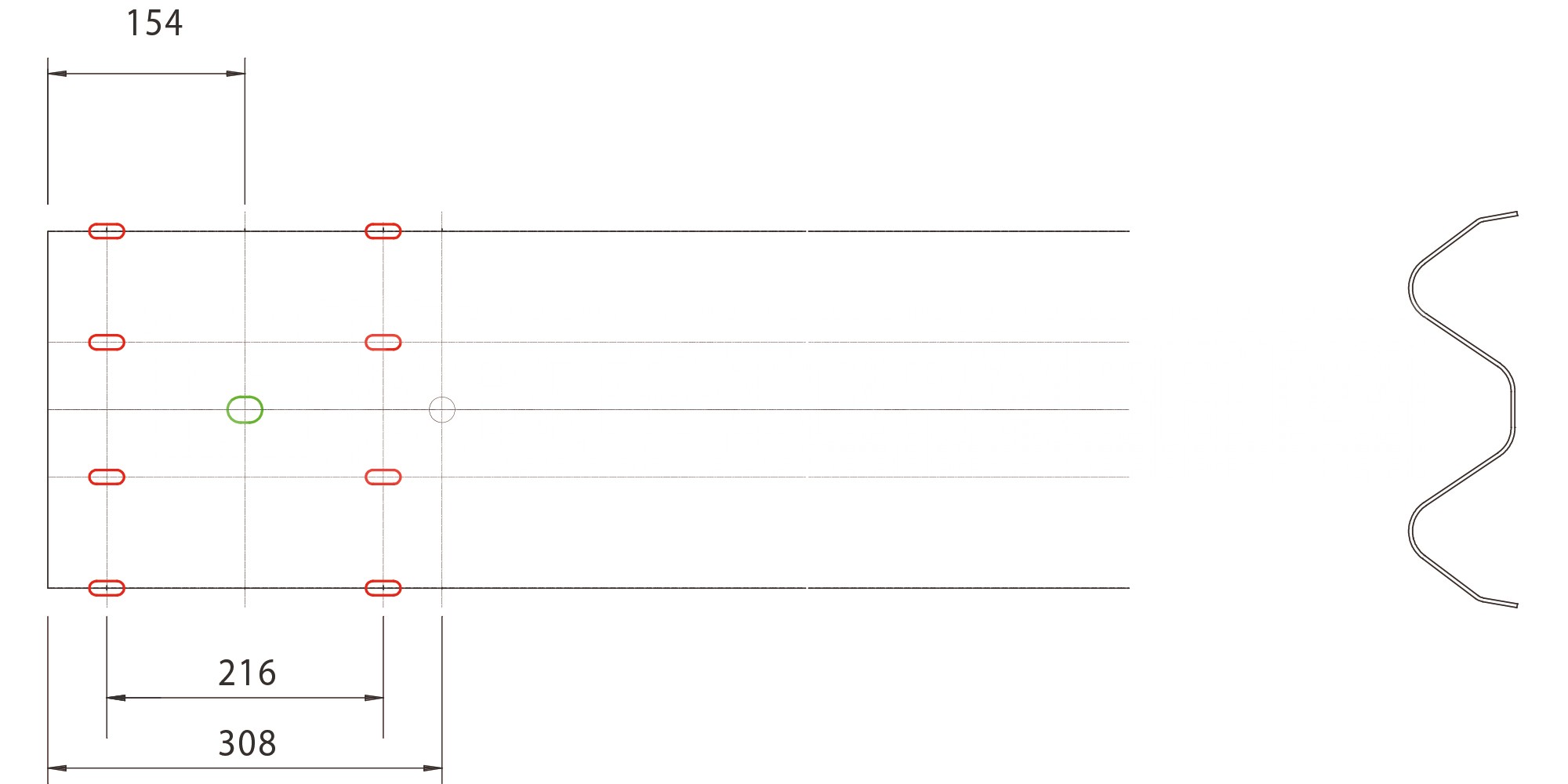

At the end of each piece there are 9 holes.

- 8 of these holes are for Lap bolts. These bolts secure the ends to each other. Each lap bolt is M16x35mm.

- 1 centre hole is for the Post bolt. This is the bolt that secures the crash barriers to the upright posts.

The diagram below illustrates this.

Lengths of barrier

There are two lengths that are commonly referred to when talking about impact barrier lengths:

- Actual length: This is the total length of the barrier from the very end to end.

- Effective length: This is the length between the post bolt holes. This is also the post spacing.

For example, if you fixed together two pieces of 3.5m (3.2m effective) impact barrier, distance between posts at each end would be 6.4m, with a length from end to end being 6.4 + 0.15 + 0.15 = 6.7 metres.

Post Spacing

Depending on the application, you can space your posts at either 3.2 metres or 1.6 metres. A post spacing of 1.6m will obviously offer a lot more protection and strength once installed.

Post Types and Mounting

There are two types of post available and two types of mounting system. Post types include:

- Z section – This is the most economical type of post available and is formed from a single piece of 5mm steel plate – forming a ‘Z’ shape when looking from above.

- RSJ / ‘I’ Beam – This follows the same shape as many RSJ beams used in construction. They are considerably more expensive but are the strongest type available.

Both types are available in:

- Bolt down – The post is welded to a large plate that is designed to be bolted down with our impact barrier bolts.

- Cast in – The post is designed to be set into concrete.

Corners and Finishing a Run of Impact Barrier

Typically it is advised to allow an additional 0.5m from the post to the apex of the corner. Our flexible corners can be bent from the standard 90 degrees to other angles to suit your application.

Tolerances of Impact Barriers

When designing an impact barrier application on paper it is common to design to very precise measurements – and this in turn usually adds significant cost as custom lengths are required to meet these dimensions.

In reality, because of the scale of impact barrier installations being within half a metre of the perfect length will often be good enough. This avoids having to have increased costs, lead times and instead we are able to deliver direct from stock without any waiting.